More Than 40 Years of Experience & 450 Direct Employees Including

The Largest and Most Modern Seat Belt Manufacturer in Iran

Akhshan Industrial Company, seat belts producer

for variety of vehicles

Renault Sandero (B90)

Tondar 90

Arisan Pickup

Peugeot Arian SD

Peugeot 206

Peugeot 207

Peugeot Pars

Peugeot 405

Samand

Dena & Dena+

Runna

Soren

Pride

Tiba

Saina

Pickup (Nissan, Peykan)

And all of the Iran Khodro’s export products

The company takes advantage of the most modern technology and mechanisms of the world such as ‘the Pretentioner’ and ‘the Load Limiter’ systems in manufacturing the products.

The first colored seat belt producer in Iran

Renault Sandero (B90), Tondar 90, Arisan Pickup, Peugeot Arian SD, Peugeot 206, Peugeot 207, Peugeot Pars, Peugeot 405,

Samand, Dena & Dena+, Soren, Pride, Tiba, Saina, Nissan & Peykan Pickup

Engineering Dept.

Engineering Dept.

Design of products in accordance with customer standards and tools, design of processes and making assembly lines

Planning & Logistics Dept.

Planning & Logistics Dept.

Relies on the modern techniques and production planning and supply management responsible and organizing different production lines

Quality Management

Quality Management

Continuous improvement of the quality cycle (PDCA) to achieve zero defects with respect to the prevention culture rather than correction

Assembly Unit

Assembly Unit

Various semi-automatic assembly lines and using poka yoke (anti-error technique)

Laboratory Unit

Laboratory Unit

Accredited by Iran National Standard Institute by having various equipment in compliance with National Standards

Molding & Tool Making Unit

Molding & Tool Making Unit

Has advanced dye-casting machinery and equipment such as CNC, Spark, and Wire-cut and also experienced personnel

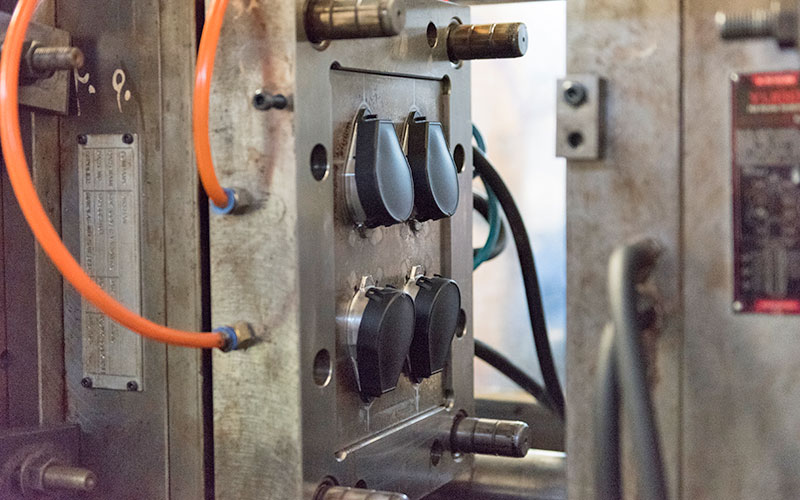

Plastic Injection Unit

Plastic Injection Unit

Various kinds of vertical and horizontal plastic injection machines with the capacity of 1 to 320 grams

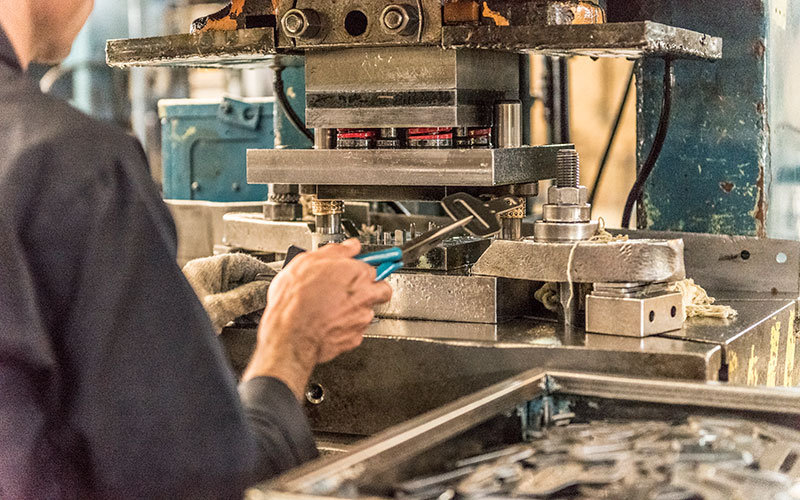

Press Hall

Press Hall

Equipped with hydraulic and stamping press machines in a wide tonnage range (from 20 to 1000 MT)

Heat Treatment Unit

Heat Treatment Unit

Continuous and batch furnaces for heat treatment procedure.

Electrostatic Coating

Electrostatic Coating

Provides all required coating by using continuous electrostatic coating line

Weaving Unit

Weaving Unit

Installed and operated advanced machinery of twisting and weaving (Mulle , Swiss)

Electro Plating

Electro Plating

Has provided modern equipment to galvanized and make nickel- chrome coating

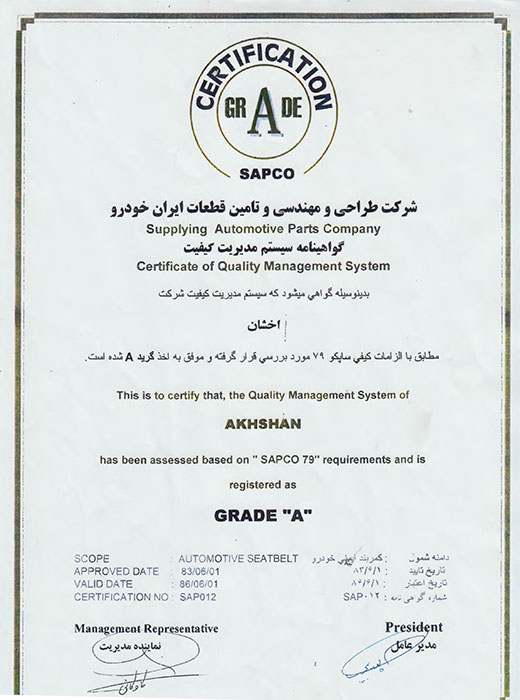

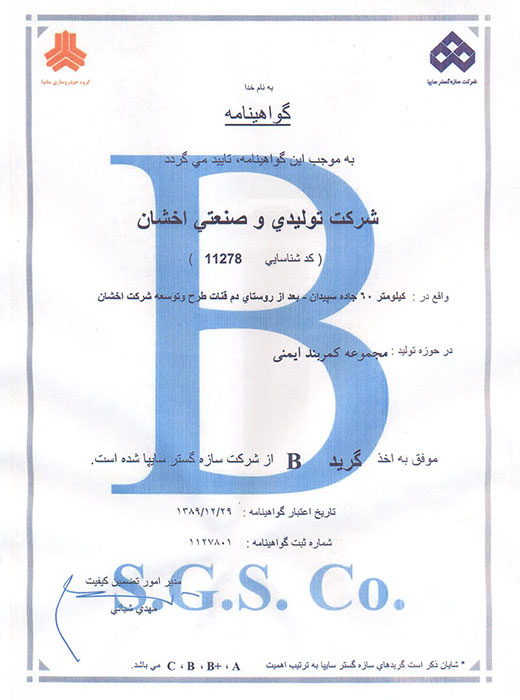

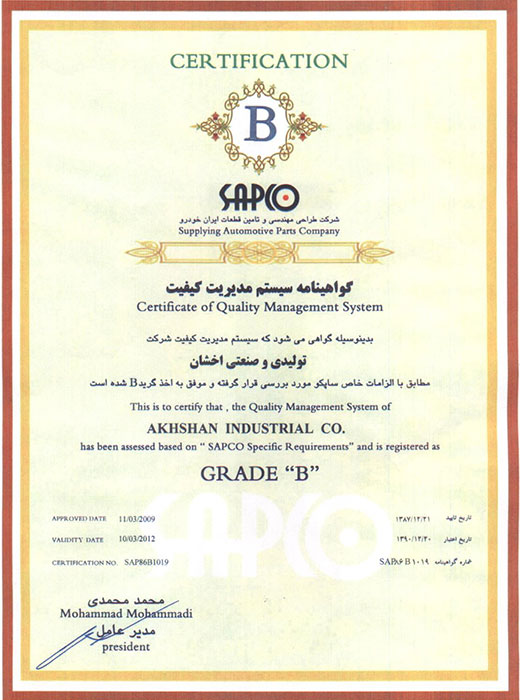

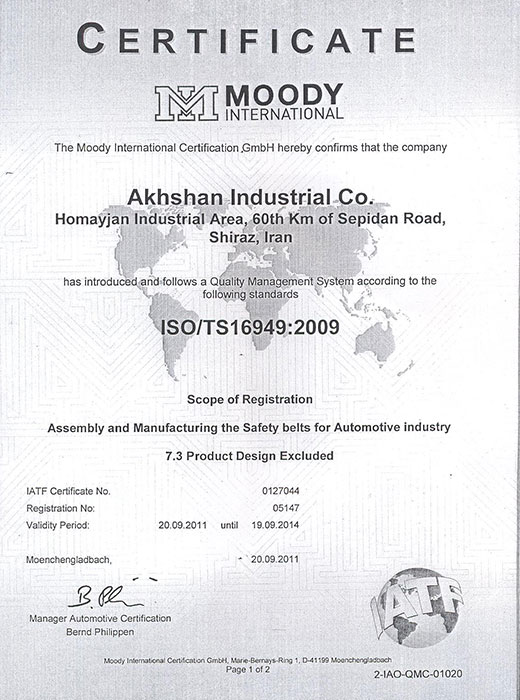

Akhshan is certified with standards of ISO 9001:2008, ISO/TS 16949, Iran National Standard, Grade ‘A’ of SAPCO and also Grade ‘B’ of SAIPA company. Akhshan IND & MFG company was selected as the exemplary manufacturing company of the year 2000 and exemplary company regarding commitment to national standards in year 2005 in Iran. Akhshan had been chosen as the best production unit in Iranian industries between P&D centers in year 2008.

CERTIFICATES

OUR CUSTOMERS & PARTNERS

The company takes advantage of the most modern technology and mechanisms of the world such as ‘the Pretentioner’ and ‘the Load Limiter’ systems in manufacturing the products.